Cooling capacity30 Ton to 200Ton

Temperature control 7℃ to 35℃, 0℃,-5℃,-10℃ to -40℃ iotional

Shell and tube evaporator and condenser

Bizer or Hanbell semi-hermetic screw compressor

Optional refrigerant R134a,R407c and R410a

Safety protection devices of whole screw chiller

All models and cooling capacity available

24/7 Online Support

86-17686681005

Description

Description

About Us

As a leading water-cooled screw chiller manufacturer with almost 18 years of experience since 2003, MGREENBELT provides a complete range of water-cooled screw chiller from MG-WS series.

The cooling capacity of screw water chiller is from 30Ton to 500 Ton/105KW to 1750KW and the chiller temperature control range from +30℃ to -40℃.

Besides the standard water-cooled screw chiller control temperature from 7℃ to 30℃, MGREENBELT also has a water-cooled glycol screw chiller control temperature below zero from 0℃ to -40℃ for some special industrial applications.

With 18 years experience in design and manufacturing water-cooled screw chiller from MGREENBELT has the following features:

Using famous brand Semi-hermetic Screw Compressor- Bitzer from Germany and Handbell from Taiwan.

Each screw compressor comes with 4 steps of energy control 0-25%-50%-75%-100% to make sure the whole screw chiller operates when stable with high refrigeration performance.

Each water-cooled screw chiller with high-efficiency shell and tube type heat exchanger and aluminum foil with a copper tube air cooled condenser.

Integrated PLC control system with human-computer interface and big LED touch screen panel for easy operation.

Other refrigeration parts are world famous refrigeration spare parts like Danfoss thermal expansion valve, Alco dryer filter, Schneider contactor, and overload relay will make sure the whole screw chiller works under normal condition.

Compared with air cooled screw chiller, water cooled screw chiller should run together with external cooling tower and water pump. This is the biggest difference between air cooled screw chiller and water cooled screw chiller.

As a professional water cooled screw chiller manufacturer, MGREENBELT has exported many water cooled screw chillers to the Philippines, Australia, New Zealand, Malaysia, Singapore, Indonesia, Chile, Mexico, Costa Rica, Brazil, Argentina, Colombia, South Africa, Nigeria, Saudi Arabia, Dubai, Spain, Italy, etc.

If you are searching for a water-cooled screw chiller supplier, you are coming to the right place. MGREENBELT is a high reputation brand in the refrigeration market.

If you have any water-cooled screw chiller inquiry, please contact our engineering for a solution and free quotation.

Application

MG-WS series Water Chiller are widely used in the Plastic industry, Electrons, Plating, Chemical Industry,Food and beverage, Ultrasonic wave cooling, Printing and other industrial production. It can precisely control the exactly temperature , which requested by the modernized machinery production, and greatly improved the production efficiency and product quality. MGREENBELT Industrial chiller is a good partner for the modernized industry , which feather as easy to operate with reasonable design, high quality and complete range of specifications.

Parameter

Parameter

|

Model |

MG-90W |

MG-125W |

MG-165W |

MG-180W |

MG-220W |

MG-240W |

MG-280W |

|

|

Capacity |

USRT |

26.2 |

35.8 |

46.6 |

50.3 |

62.3 |

67.1 |

79.6 |

|

Kcal/h |

79120 |

108360 |

141040 |

152220 |

188340 |

202960 |

240800 |

|

|

KW |

92 |

126 |

164 |

177 |

219 |

236 |

280 |

|

|

Power |

3PH-380V-50Hz |

|||||||

|

Refrigerant |

Type |

R22 |

||||||

|

Control |

Thermostatic expansion valve |

|||||||

|

Comperssor |

Type |

Semi-closed screw type |

||||||

|

kw Power |

23 |

32 |

39 |

42 |

54 |

57.5 |

65 |

|

|

Start |

Y-△ |

|||||||

|

Capacity |

25-50-75-100(%) or 25-100(%) |

|||||||

|

Evaporator |

Type |

High efficiency copper tube shell and tube type |

||||||

|

m³/h Flow |

15.8 |

21.6 |

28.1 |

30.3 |

37.5 |

40.5 |

48.0 |

|

|

Inlet/Outlet |

DN50 |

DN65 |

DN80 |

DN80 |

DN80 |

DN80 |

DN100 |

|

|

Condenser |

Type |

High efficiency threaded copper tube shell and tube type |

||||||

|

m³/h Flow |

21.7 |

29.8 |

38.3 |

41.3 |

51.5 |

55.3 |

65.1 |

|

|

Inlet/Outlet |

DN50 |

DN65 |

DN80 |

DN80 |

DN80 |

DN80 |

DN100 |

|

|

Protection System |

Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. |

|||||||

|

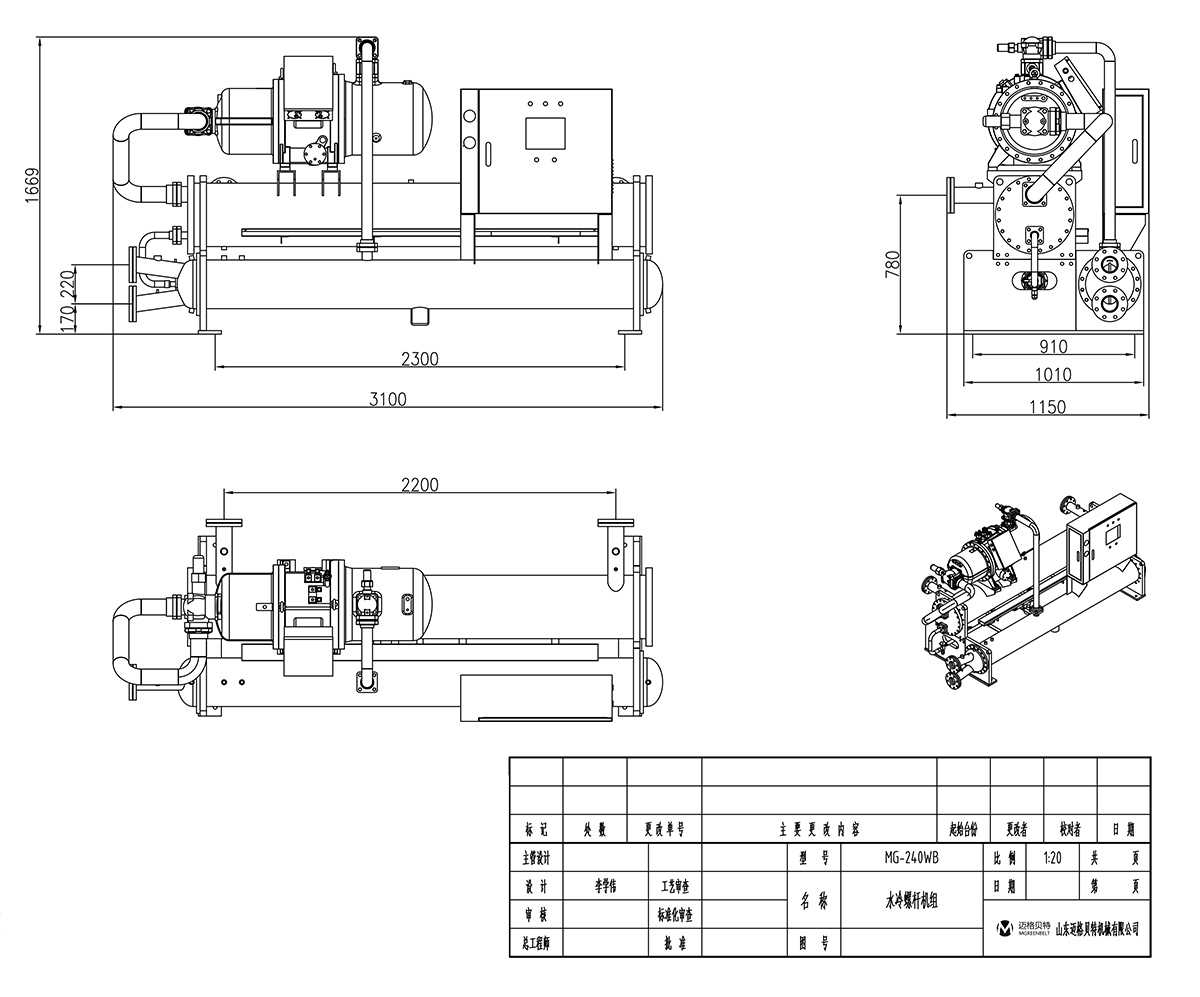

Dimension |

L |

2300 |

2500 |

2500 |

2500 |

2800 |

2800 |

3200 |

|

W |

750 |

750 |

750 |

750 |

800 |

800 |

800 |

|

|

H |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

|

Weight |

kg |

660 |

700 |

800 |

975 |

1000 |

1150 |

1250 |

|

Model |

MG-300W |

MG-350W |

MG-500W |

MG-600W |

MG-650W |

MG-750W |

MG-800W |

|

|

|

USRT |

83.9 |

100.1 |

145.3 |

173.7 |

182.0 |

210.4 |

227.5 |

|

Kcal/h |

253700 |

302720 |

439460 |

525460 |

550400 |

636400 |

688000 |

|

|

KW |

295 |

352 |

511 |

611 |

640 |

740 |

800 |

|

|

Power |

3PH-380V-50Hz |

|||||||

|

|

Type |

R22 |

||||||

|

Control |

Thermostatic expansion valve |

|||||||

|

|

Type |

Semi-closed screw type |

||||||

|

kw Power |

70 |

78 |

86 |

104 |

106 |

118 |

128 |

|

|

Start |

Y-△ |

|||||||

|

Capacity |

25-50-75-100(%)或25-100(%) |

|||||||

|

|

Type |

High efficiency copper tube shell and tube type |

||||||

|

m³/h Flow |

50.6 |

60.3 |

87.6 |

104.7 |

109.7 |

126.9 |

137.1 |

|

|

|

DN100 |

DN100 |

DN100 |

DN100 |

DN125 |

DN125 |

DN125 |

|

|

|

Type |

High efficiency threaded copper tube shell and tube type |

||||||

|

m³/h Flow |

68.8 |

81.1 |

112.6 |

134.8 |

140.7 |

161.8 |

175.0 |

|

|

Inlet/Outlet |

DN100 |

DN100 |

DN100 |

DN100 |

DN125 |

DN125 |

DN125 |

|

|

|

Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. |

|||||||

|

|

L |

3200 |

3500.0 |

3500.0 |

3500 |

3800 |

3800 |

3800 |

|

W |

800 |

900 |

900.0 |

900 |

900 |

1200 |

1200 |

|

|

H |

1500 |

1500 |

1800.0 |

1800 |

1800 |

1800 |

1800 |

|

|

Weight |

kg |

1400 |

1600 |

1750 |

1750 |

1850 |

2000 |

2000 |

Main Specification:

1) .Cooling capacity from 7℃ to 35℃, or if need lower outlet temperature please inform us change the offer;

2) .Stainless insulated water tank and anti-freeze thermostat can provide from us;

3) .R22/R407c/R404a/R134a refrigerant used as standard for efficient cooling.

4) .Refrigeration loop controlled by high and low pressure switches.

5) .Compressor and pump overload relays.

6) .Tube-in-shell condenser design for quick heat transfer and excellent heat radiation.

7) .Tube-in-shell evaporator for excellent cooling.

Details

Details

Advantage of Screw Industrial Water Cooled Chiller

1. Higher COP due to water cooled lower condensing temperature , usually 35-45C

2. Can be installed indoor and outside house

3. Water cooled screw chiller just need small size

4. Require external cooling tower for condenser, ensure higher cooling efficiency

5. widely used in large cooling project, very suitable hot ambient temperature

Structural

Structural

Professional Industrial Refrigeration Equipment Solution Provider.